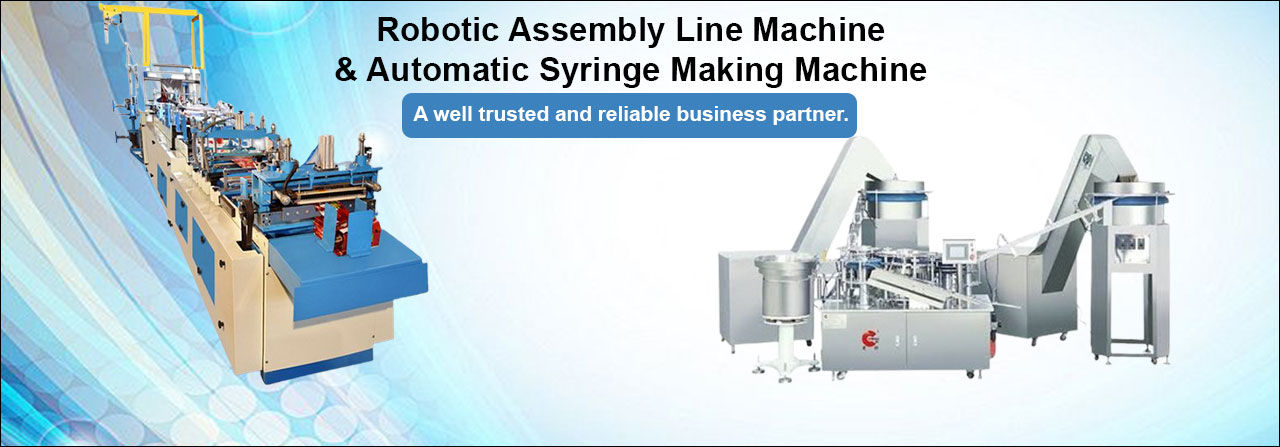

Avail the best quality of Industrial Three Phase Automation System, Robotic Assembly Line Machine, Three Phase Vision Inspection System, etc..

About Us

We, Imatics, are a medium-sized manufacturer and supplier of industrial automation equipment and special purpose machines situated in Chennai. Since 2018, we have been providing bespoke factory automation on turnkey basis to a variety of sectors. Customers can avail Flexible Roller Conveyor, Semi Automatic Special Purpose Assembly Machine, Three Phase Syringe Making Machine, Three Phase Box Packaging Machine, etc. The products we supply are defect-free and made using the best components and latest technology. With the help of our logistics associates, we deliver the consignments to the doorstep of clients.

We, Imatics, are a medium-sized manufacturer and supplier of industrial automation equipment and special purpose machines situated in Chennai. Since 2018, we have been providing bespoke factory automation on turnkey basis to a variety of sectors. Customers can avail Flexible Roller Conveyor, Semi Automatic Special Purpose Assembly Machine, Three Phase Syringe Making Machine, Three Phase Box Packaging Machine, etc. The products we supply are defect-free and made using the best components and latest technology. With the help of our logistics associates, we deliver the consignments to the doorstep of clients.

Make your

enquiry now !

Talk to us! we will be glad to assist

you.

Product Gallery

-

Fully Automatic Syringe Barrel Printing Machine -

Syringe Barrel Moulds -

Insulin Syringe Needle Assembly Machine -

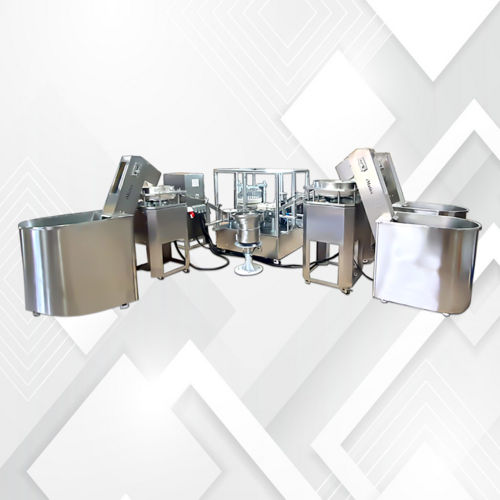

Automatic Syringe Assembly Machine -

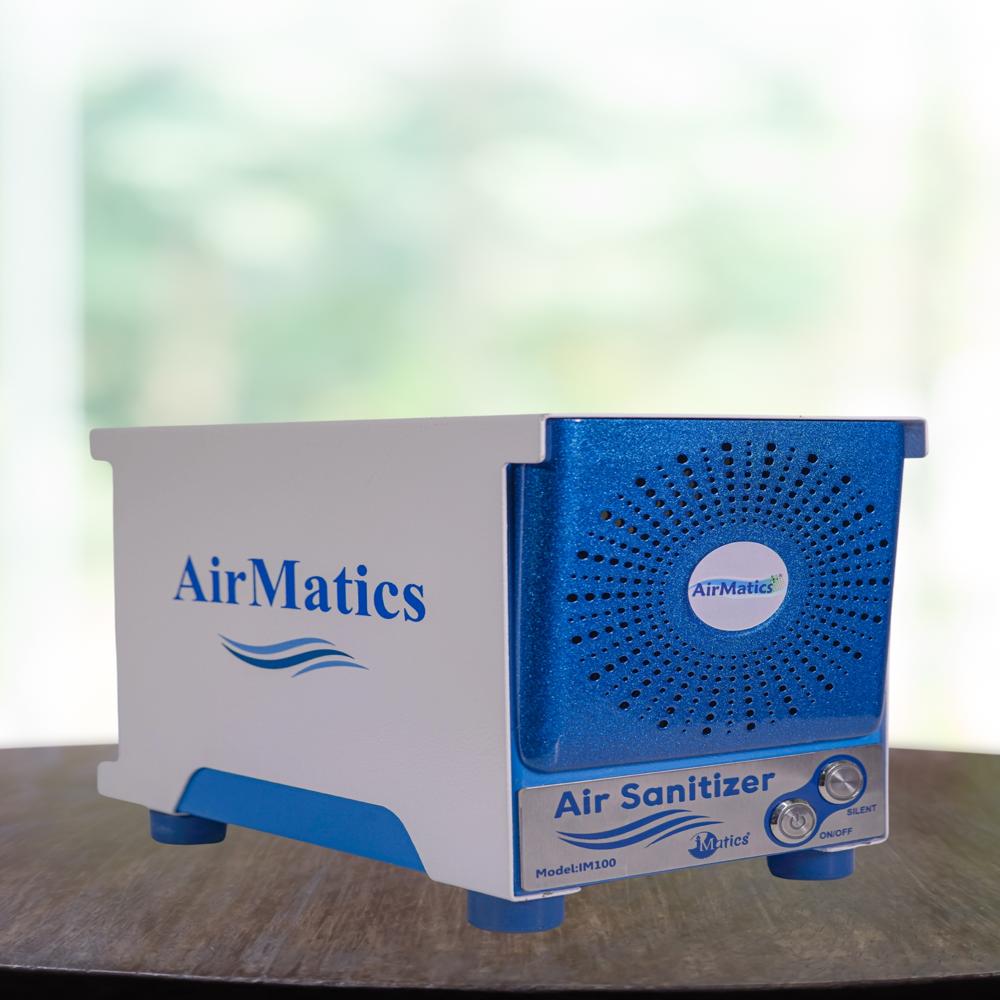

Indoor Air Purifier -

Automatic Air Sanitizer -

Air Purifiers -

PET Tube Injection Moulding Machine -

Blood Collection Tube Labelling Machine -

Coagulant BCA dosing Machine -

EDTA dosing Machine -

Clean Room Structure -

Blister Packing Machine -

Fully Automatic Blister Packing Machine -

Actuator Assembly Line SPM Machines -

Automobile Door Wind Shield Holder Assembly -

Roller Conveyor Line -

SS Material Handling Conveyor -

Luer Unsterile Syringe -

Auto Disable Syringe 0.5 Ml -

Digital Vibrator Controller -

Analog Vibrator Controller -

Robotic Assembly Line Machine -

Pneumatic Assembly Line Machine -

Disposable Syringe Packing Machine -

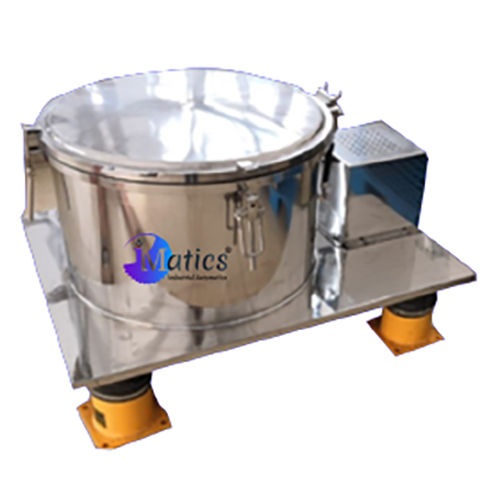

Centrifugal Bowl Feeders -

Automatic Box Packaging Machine -

ETO Sterilizer Machine -

Card Pasting And Stacking Machine -

Industrial Automation System -

Material Handling Belt Conveyor -

UVC Disinfection System -

Ribbon Packing Machine

We take pleasure in our unique capacity to manufacture Pneumatic, Electronic Controls, Mechanical, Special Purpose Machines with Design, Material Handling, Hydraulic and Process Engineering solutions all under one roof, allowing us to provide solution effectively. Our innovative ideas enables us to provide the best value to customers through cost and time management efficiencies. We have deep knowledge and have track of completing large number of successful projects.

Multi-Disciplined Approach

We have the resources and ability set to take on projects of any scale and in any sector. We also have the flexibility and customer focus to adjust to shifting project with time frames and scope. We have the ability and resources to satisfy customers demands, whether they need entire bespoke automation or just a single service. Our crew is well-versed with the knowledge and is producing Semi Automatic Special Purpose Assembly Machine, Flexible Roller Conveyor, Three Phase Box Packaging Machine, Three Phase Syringe Making Machine, etc. As a result, we are able to complete projects of any scale or complexity. This ensures that your project stays on schedule, even if timelines, project parameters, and other variables change.

Our Mission and Vision

To offer the best Automation solution by combining a wide range of resources, cutting-edge technology with the help of a highly trained team of professionals with a commitment to client satisfaction.

Through cutting-edge automation technologies, create superior, cost-effective solutions that improve customer success. Through mutually profitable growth, generate concepts and give specialized services to customers.

Industries

To our customers, we provide products to achieve their lean manufacturing targets. Lean production is a practice that improves corporate performance by streamlining operations and increasing customer value by methodically eliminating waste. One can get the following results by taking a lean approach to industrial automation:

- Recognize and surpass the expectations of your customers.

- Dramatically improved quality. Errors and faults will be drastically reduced.

- Identify and eliminate waste in processes.

- Make your operations easier to manage by simplifying them.

- Reduce the cost, cycle time, and time to market your products.

- Create the opportunity to reach your strategic objectives more quickly.

Our Experience

Our clients rely on us to come up with creative and intelligent solutions to fulfil their specific needs associated with Three Phase Syringe Making Machine, Three Phase Box Packaging Machine, Flexible Roller Conveyor, Semi Automatic Special Purpose Assembly Machine, etc. We have built a solid reputation for inventing and producing cutting-edge automation equipment and solutions. With our portfolio of innovative products we are serving a wide range of industries, including medical, automotive, electrical, food, pharmaceutical and industrial safety.

Our People

Our engineers have a lot of experience working with customers to transform automation ideas into products that help them develop and perform better in the future. Our professionals come from a variety of disciplines and are experts in Design, R&D, Engineering, Technology and Lean Manufacturing. They have a profound technical understanding of a variety of product applications.

Our Capabilities

Everything begins with clients requirements, which is then thoroughly examined from all angles. We work step by step from the beginning, from design through engineering, manufacture, and assembly, all the way to testing. During the intensive development phase, our engineers will collaborate closely with the customer to ensure that the final implementation is completed within the constraints of available resources.

Our Facilities

Our in-house teams in Chennai are responsible for the designing and development of numerous Custom Products and technologies. Our dedication to offering a smooth innovation process for our customers, from concept to manufacturing, is demonstrated by our ongoing investment in maintaining first-class facilities.

Our Products: Your Label

We design and manufacture unique projects for a wide range of clients and worldwide OEMs in a variety of industries. We are happy to work with major manufacturers in a variety of industries, including healthcare, automobiles, engineering, plastics, electrical, pharmaceuticals, and food.

Application

- Machining Automation

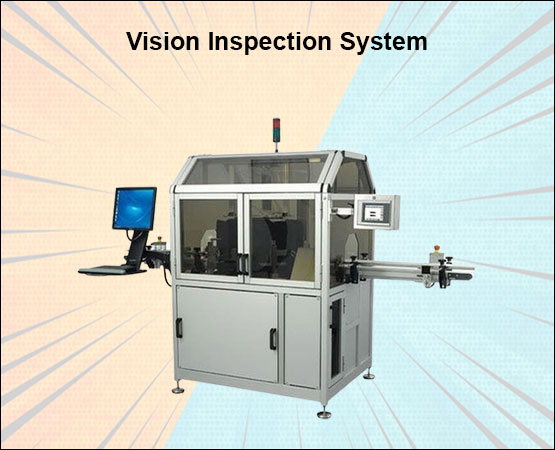

- Inspection Automation

- Material Handling

- Pick & Place

- Packaging Automation

- Product Assembly Automation

- Process Automation

Technologies & Industries Served

Imatics has developed superior technology and worked with customers in practically every industry. Every industry faces its own set of challenges, but there is not one for which we cannot find a solution. In todays fast-changing manufacturing environments, automation is essential. Companies require a single, straightforward response to complex problems. We are confident in our ability to make your industry perform smarter, faster, safer, and more efficiently than it has in the past. Further, many of our clients believe the changes we made to their operations have given them a competitive edge. As a result, we maintain their projects in exceptionally well manner.

|

Industries |

Technologies |

|

|

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese