Fully Automatic Syringe Barrel Printing Machine

Product Details:

- Product Type Syringe Barrel Printing Machine

- Material Stainless Steel (SS)

- Capacity 12000-15000 Pcs/min

- Computerized No

- Automatic Grade Automatic

- Control System PLC Control

- Voltage 440 Volt (v)

- Click to View more

Fully Automatic Syringe Barrel Printing Machine Price And Quantity

- 1000000 INR/Unit

- 1 Unit

Fully Automatic Syringe Barrel Printing Machine Product Specifications

- PLC Control

- Automatic

- Silver

- 750 Kilograms (kg)

- No

- 1500 Watt (w)

- 2500x2000x1800 Millimeter (mm)

- 440 Volt (v)

- Syringe Barrel Printing Machine

- Stainless Steel (SS)

- 12000-15000 Pcs/min

- 1 Year

Fully Automatic Syringe Barrel Printing Machine Trade Information

- CHENNAI

- 6 Unit Per Year

- 2 Months

- Wooden Box

- Asia Australia Central America North America Africa South America Eastern Europe Western Europe Middle East

- All India

- ISO 9000:2015

Product Description

The IMPAR series rotary pad printing machine various feeding systems can be integrated with the accepted moulded syringe barrel in bulk and to sort orientated and feeding these into the machine in a fully automated operation This feeding system include centrifuge and linear conveyors with servo drive part loading systemdivdiv styletextalign justifybr divdiv styletextalign justifystrongAdvantages strongdivdiv styletextalign justifybr divdiv styletextalign justifyFullauto Rotary Printing Machine of Syringe has adopted the variablefrequency governor and high efficiency and energy saving With safety cover stop running immediately when open it The machine has several advantages The production efficiency for the rotary printing machine is savaral times more than traditional screen printing The printing area has adopted a drumtype silicon rubber wheels and embossing seal which can effectively reduce the wastage of printing ink With characteristics of smooth gear drive and low noise Accurate positioning high pass rate of production

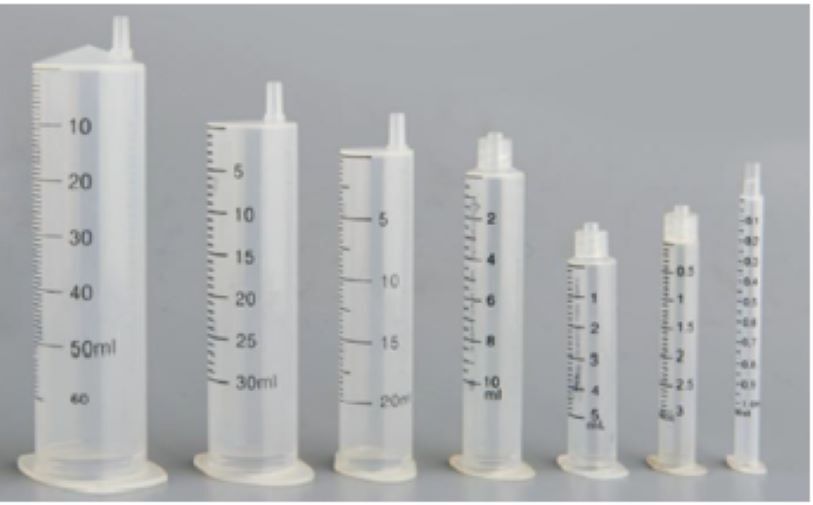

Injection moulding machine is used to produce syringe plunger and barrel in different specification and design. The machine can fulfill the detailed requirement of customers. It has mold adjustment device and multi-point hydraulic ejector device for more advanced operation. Injection moulding machine is controlled through a microprocessor. Its PLC control allows for efficient operation.

Main Technical Parameters:

- Production Capacity 12000 15000 pcsh

- Part Feeding Automatic using Centrifugal feeder with loading bunker conveyor

- Power 15KW three phase 440V

- Overall dimension L x W x H 2500x2000x1800mm

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese