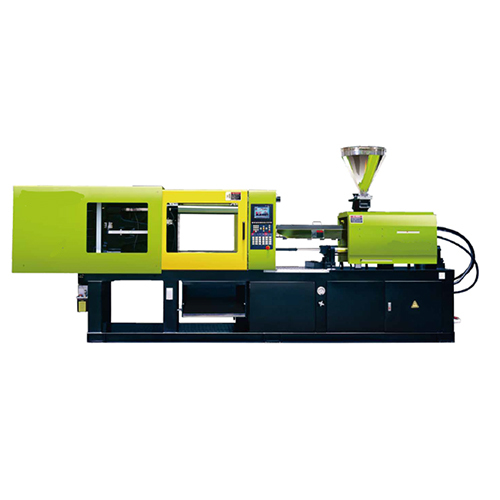

Injection Moulding Machines

Product Details:

- Product Type Injection Moulding Machines

- Material Steel

- Computerized No

- Automatic Grade Semi-Automatic

- Control System PLC Control

- Voltage 220 Volt (v)

- Color Green & Black

- Click to View more

Injection Moulding Machines Price And Quantity

- 1 Unit

- 2000000 INR/Unit

Injection Moulding Machines Product Specifications

- Injection Moulding Machines

- Semi-Automatic

- Steel

- No

- 1-2 Years

- Green & Black

- PLC Control

- 220 Volt (v)

Product Description

Injection moulding machine is used to produce syringe plunger and barrel in different specification and design. The machine can fulfill the detailed requirement of customers. It has mold adjustment device and multi-point hydraulic ejector device for more advanced operation. Injection moulding machine is controlled through a microprocessor. Its PLC control allows for efficient operation.

Injection moulding machine is used to produce syringe barrel and plunger in any specification and design. We have complete sizes of syringe part injection moulding machines we will choose the most suitable machine according to customers detailed requirement

- Controlled by microcomputer, which makes the work reliable and automatic in high level.

- Using Screw for feeding raw material, allowing processing of various materials. Strong plasticizing ability makes the injection speed high.

- Using resistance heating coils to heat the barrel, adopting cold screw protecting device, the screw will not operate until the temperature reaches the setting value.

- Adopts electrical and mechanical double safety device. The mold will not clamp when the door is open, which makes the production process safer and reliable.

- Multi-point hydraulic ejector device can choose the suitable number of ejector rod according to the actual working needs. It makes the demolding more even.

- Mould adjustment device is drive by hydraulic controlled gear transmission, which is easy for operation.

|

Model |

|

IM -100 |

IM -130 A |

IM -160 A |

|||

|

Injection |

Unit |

A |

B |

A |

B |

A |

B |

|

Screw Diameter |

mm |

36 |

38 |

38 |

40 |

42 |

45 |

|

Shot Size |

cm3 |

143 |

180 |

210 |

228 |

318 |

362 |

|

Shot Weight |

g |

128 |

162 |

188 |

205 |

386 |

326 |

|

Injection Pressure |

Mpa |

183 |

164 |

176 |

160 |

174 |

151 |

|

Injection Rate |

g/s |

90 |

98 |

95 |

100 |

135 |

155 |

|

Screw L/D Ratio |

L/D |

21.6 |

20.5 |

22.8 |

21.7 |

22.3 |

20.8 |

|

Screw Speed |

r.p.m |

0-190 |

0-190 |

0-190 |

|||

|

Nozzle Diameter |

Srmm |

0-10 |

0-10 |

0-10 |

|||

|

CLAMPING UNIT |

|||||||

|

Clamp Tonnage |

KN |

1000 |

1320 |

1650 |

|||

|

Toggle Stroke |

mm |

320 |

350 |

400 |

|||

|

Mould Thickness |

mm |

150-400 |

150-420 |

170-440 |

|||

|

Space Between Tie-bars |

mm |

385x350 |

410x375 |

455x425 |

|||

|

Ejector Stroke |

mm |

125 |

135 |

155 |

|||

|

Ejector Tonnage |

KN |

50 |

50 |

70 |

|||

|

Ejector Number |

Piece |

5 |

5 |

5 |

|||

|

Hole Diameter |

mm |

100 |

100 |

125 |

|||

|

OTHERS |

|||||||

|

Heat Power |

KW |

7.6 |

8.2 |

8.2 |

|||

|

Max. Pump Pressure |

MPa |

16 |

16 |

16 |

|||

|

Pump Motor Power |

KW |

11 |

13 |

15 |

|||

|

Valve Size |

mm |

10 |

10 |

16 |

|||

|

Machine Dimension |

m |

4.3x1.5x1.6 |

4.5x1.6x1.7 |

5.0x1.6x1.7 |

|||

|

Machine Weight |

t |

3.4 |

3.9 |

5.0 |

|||

|

Oil Tank Capacity |

L |

180 |

200 |

250 |

|||

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese